The definition of SCR & TRIAC

A Silicon Controlled Rectifier (SCR), also known as a thyristor, is a semiconductor device used for controlling electrical power. It is a type of switch that can handle high currents and is often used in applications where the control of electrical power is necessary.

A TRIAC, which stands for "Triode for Alternating Current," is a semiconductor device used primarily for controlling electrical power in AC (alternating current) circuits. It is essentially a bidirectional version of the SCR (Silicon Controlled Rectifier).

Three-Quadrant Controlled Silicon: Three-quadrant controlled silicon operates in only three of the four possible quadrants. It can be controlled during the positive half-cycle, negative half-cycle, and the zero-crossing point (transition quadrant). This means it can conduct during the positive half-cycle, negative half-cycle, or remain non-conductive. Three-quadrant controlled silicon is typically used in applications where control of current during the positive and negative half-cycles is required.

Four-Quadrant Controlled Silicon: Four-quadrant controlled silicon operates in all four quadrants, including the positive half-cycle, negative half-cycle, and zero-crossing point (transition quadrant). This enables precise control of conduction and cutoff, regardless of whether the voltage is positive or negative. Four-quadrant controlled silicon is commonly used in applications that demand more versatile current control, such as motor control and power regulation.

The choice between three-quadrant and four-quadrant controlled silicon depends on the specific requirements of your application. If you only need to control current during the positive and negative half-cycles, then three-quadrant controlled silicon may suffice. However, if you require comprehensive current control, including operation in the transition quadrant, then four-quadrant controlled silicon may be more suitable.

SCR Product Features

Ø High voltage capability (200V to 2000V).

Ø High surge current capability (up to 5000A).

Ø Chip glass passivation.

Ø High thermal conductivity and durability.

Ø Electrical isolation packaging.

TRIAC Product Features

Ø High surge current capability (up to 1000A).

Ø High voltage capability (200V to 2000V).

High commutation dv/dt capability.

Ø Enhanced dynamic performance.

Ø High junction temperature of 150°C.

The KEY point to consider when choose SCR & TRIAC

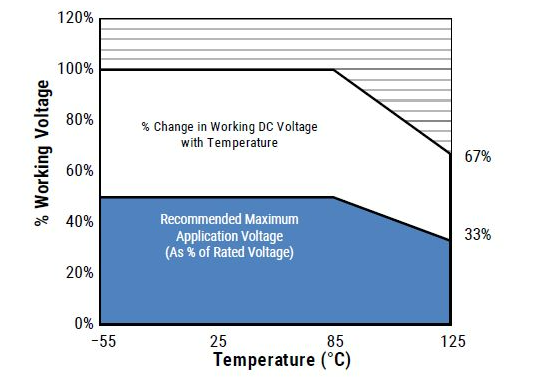

Voltage Rating: The typical voltage rating is generally 3-4 times the application voltage. For example, in regions with a mains voltage of 220V,

thyristors are typically selected with a voltage rating greater than 600V or 800V. Inadequate voltage rating can lead to breakdown of the thyristor chip.

On-State Current: The current-carrying capacity of thyristors, for discrete devices, usually ranges from 1A to 40A. The current rating is determined

by the size of the chip, and therefore, the current rating is directly proportional to the chip's size and cost.

Trigger Current: Thyristors are controlled by current, so selecting the appropriate trigger current is crucial. Choosing a current that is too large may

result in failure to trigger, while selecting one that is too small can make the trigger overly sensitive, leading to unintentional triggering (especially

when there are interference currents in the product or circuit).

Junction Temperature: Temperature tolerance is another critical parameter for thyristors. Products are typically categorized into standard

junction temperature and high junction temperature. High junction temperature products usually exceed 150°C and can effectively operate

at temperatures up to 180°C before losing control. Products intended for high-temperature environments must be carefully selected to ensure they

have high junction temperature ratings. Other parameters such as Ih, IL, dv/dt, and more also play a role in thyristor selection.

Functions of Thyristors: Rectification, inversion, frequency conversion, voltage regulation, temperature control, contactless switching, etc.

Applications of SCR & TRIAC

SCR & TRIAC are extensively used in applications such as dimmable lights, variable-speed fans, air conditioning units, refrigerators, washing

machines, cameras, stereo systems, sound and light control circuits, timers, gas igniters, toys, power tools, printers, motorcycle igniters, regulators,

and industrial control systems, including industrial boilers, among others.

SCR | ||||

Topdiode P/N# | Package | Cross to brands | Cross to P/N | Cross to package |

100-8U | TO-92 | WeEn | BT169D-L,116 | TO-92 |

100-8U | TO-92 | ST | TS110-8A2-AP | TO-92 |

100-8W | TO-223 | NXP | BT169W | TO-223 |

CR03 | TO-223 | ST | X0202MN | TO-223 |

S1215-8F | TO-220F | WeEn | TO-220F | |

S1215-8B | TO-220B | ST | TYN812RG | TO-220AB |

S1215-6D | TO-252 | ST | TN1215-600B-TR | DPAK |

S1215-8B | TO-220B | Littelfuse | TO-220R | |

S1615-8B | TO-220B | ST | TYN816RG | TO-220AB |

S1615-8F | TO-220C | WeEn | TO-220AB | |

S1615-8B | TO-220B | Littelfuse | S8016RTP | TO-220R |

S7560-12N | TO-247 | Vishay | VS-50TPS12L-M3 | TO-247AD |

S7560-12N | TO-247 | IXYS | TO-247AD | |

S5560-16N | TO-247 | WeEn | TO-247 | |

S5560-16N | TO-247 | Littelfuse/IXYS | CLA30E1200HB | TO-247 |

S7560-16N | TO-247 | IXYS | TO-247AD | |

S10060-16NS | TO-247S | IXYS | TO-247AD | |

S10060-16NS | TO-247S | Vishay | VS-70TPS16PbF | TO-247 |

TRIAC | ||||

Topdiode P/N# | Package | Cross to brands | cross to P/N | Cross to package |

T0210-8F | TO-220F | WeEn | BTA202X-800E | TO220F |

T0210-8W | SOT-223 | WeEn | BTA202W-800ET | SOT223 |

T0405-8D | TO-252 | WeEn | BTA204S-800B | DPAK |

T0405-8W | SOT-223 | WeEn | SOT223 | |

T0405-8B | TO-220B | WeEn | TO-220AB |

ts #Diode #MOSFET #cost_down #High quality.

ts #Diode #MOSFET #cost_down #High quality.